Wood Pellet Line: An Encyclopedic Guide to Biomass Pellet Production Systems and Global Applications

Introduction The growing demand for renewable energy and sustainable resource utilization has led to increased…

Introduction The growing demand for renewable energy and sustainable resource utilization has led to increased interest in biomass processing technologies. Among these, wood pellet production has become one of the most widely adopted methods for converting forestry residues into standardized solid fuel. Central to this process is the wood pellet processing equipment, a complete system…

The concept of sustainability has become a driving force in many industries, and organic fertilizer production is no exception. The agricultural sector, in particular, has seen a growing need for eco-friendly and energy-efficient solutions to meet both environmental concerns and consumer demand for sustainable products. Integrating renewable energy sources into organic fertilizer production lines is…

1. Introduction In recent years, the global agricultural industry has been increasingly focused on sustainable development, and the production and use of organic fertilizers have gained significant momentum. Organic fertilizer pellet machines play a crucial role in the production process of organic fertilizers by transforming various organic raw materials into granulated fertilizers. From an environmental…

When it comes to pellet production—whether for animal feed, biomass, or organic fertilizer—the durability of your pellet mill determines everything from uptime and maintenance costs to product consistency and ROI. So, which pellet mill manufacturer actually delivers the most durable machines in the global market? Let’s cut through the noise and get straight to the…

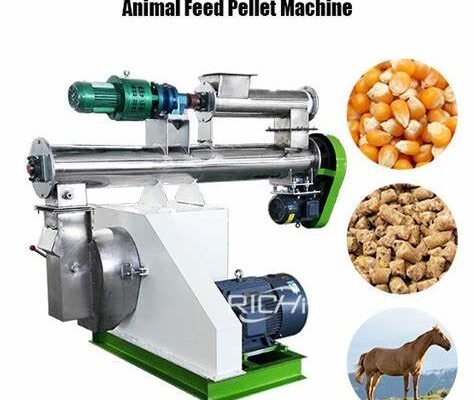

Introduction to Animal Feed Pellet Mill Machines An animal feed pellet mill machine is a pivotal tool utilized in the agricultural sector, designed to convert raw feed ingredients into compact, digestible, and convenient pellet form. These machines essentially take raw materials such as grains, soybean meal, maize, and other nutritional elements, compressing them into uniform…

Types of Animal Feed Pellets for Poultry The production of animal feed pellets using a pellet making machine for poultry feed encompasses various types that cater to the unique dietary needs of different poultry species such as chickens, ducks, turkeys, and more. These feed pellets are formulated using diverse ingredients to furnish balanced nutrition, ensuring…

Producing high-quality feed for broiler chickens is essential for poultry farmers aiming to maximize growth rates, feed efficiency, and overall profitability. The right animal feed production machines play a crucial role in ensuring that the feed meets the nutritional requirements of broilers while maintaining consistency and quality. This article outlines the key machines suitable for…

The efficiency of a 10 t/h animal feed manufacturing machine is crucial for feed producers aiming to meet the growing demand for high-quality animal feed. Several factors can significantly influence the production efficiency of these machines, impacting output, quality, and operational costs. Understanding these factors is essential for optimizing performance and ensuring profitability. This article…

In the competitive landscape of the animal feed industry, maximizing production efficiency is crucial for profitability and sustainability. A 10 t/h animal feed manufacturing machine is designed to meet the demands of small to medium-scale operations, and optimizing its performance can lead to significant benefits. This article explores common methods that can be employed to…

The animal feed industry is undergoing significant transformation with the advent of automation technologies. As the demand for high-quality animal feed continues to rise, feed manufacturers are increasingly looking for ways to enhance production efficiency, reduce labor costs, and improve product quality. A 10 t/h animal feed manufacturing machine, which is suitable for small to…