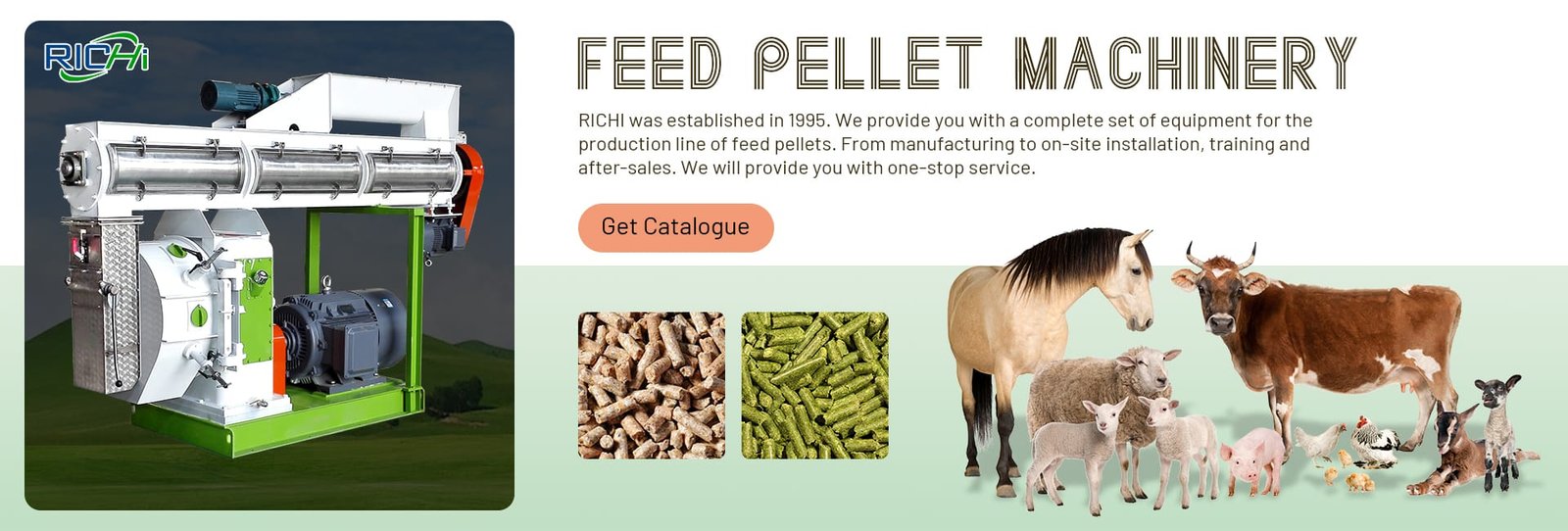

The feed pellets produced by the RICHI wholesale 1-40t/h ce iso factory supply poultry pellet feed machine with less cost, have high hardness, smooth surface and internal curing, which can improve the digestion and absorption of nutrients.

The pellet formation process can denature the pancreatic enzyme resistance factor in grains and beans, reduce the adverse effects on digestion, kill various parasite eggs and other pathogenic microorganisms, and reduce various worms and digestive system diseases.

Compared with mixed powder feed, higher economic benefits can be obtained. High temperature and high pressure are generated during the pressing process, the feed has a strong paste aroma, and the feed texture is hard, which is in line with the characteristics of chickens, ducks, poultry, pigs, cattle, and sheep.

The nutrient absorption conversion rate is increased by 300%, non-toxic and sterile, and the volume of the straw is doubled after pelleting by poultry feed pellet making machine, which is convenient for long-term storage and transportation. (Related post: Feed mill plant in Uzbekistan)

1.What are the advantages of the poultry pellet feed machine?

(1) The poultry feed pellet making machine has reasonable design, simple operation, no noise;

(2) Small machine with high output, low energy consumption, dry in and dry out;

(3) High forming rate, high hardness; smooth surface; convenient for transportation and storage;

(4) Different types of grinding discs are suitable for granulation of different materials;

(5) The poultry pellet feed machine apply different materials to ensure the pressing effect;

(6) Simple operation and maintenance, safe and reliable;

(7) Strong adaptability to the workplace;

(8) Solid structure, beautiful appearance and long service life.

2.Why buy RICHI poultry feed pellet making machine?

(1) Features of 1-10T/H poultry pellet feed machine

- Compact structure and beautiful appearance;

- High output, low power consumption, easy to use and reliable performance;

- The pressure rollers are evenly arranged, the operation is stable, and the pressing area is increased to improve the production efficiency;

- The gap between the poultry feed pellet making machinemolds can vary from size to size, suitable for different materials to ensure the pressing effect;

- There is an observation door, which can be checked at any time for easy maintenance and repair.

(2) Features of 11-20T/H poultry pellet feed machine

- Compact structure, beautiful appearance, high output and low power consumption;

- The poultry pellet feed machine pressure rollers are evenly arranged, and the operation is stable;

- The gap between the molds can vary from size to size, suitable for different materials to ensure the pressing effect;

- There is an observation door, which can be checked at any time for easy maintenance and repair.

(3) Features of 21-40T/H poultry pellet feed machine

- Scientific and reasonable structural design, simple, small footprint, low noise;

- Dry in and dry out, easy to make materials, high output and low energy consumption;

- High pelletforming rate, high hardness, smooth surface, convenient for storage and transportation;

- Poultry pellet feed machineadapts to different materials to ensure the pressing effect;

- The body is cast as a whole, the structure is firm and the appearance is beautiful, and the service life is long.

3.Customize the poultry pellet feed machine plan for you:

Richi Machinery complete set of poultry pellet feed machine, feed processing and production equipment independently developed and developed by our company, common matching equipment includes: crushing equipment, feeding equipment, drying equipment, pelletizing equipment and cooling and packaging equipment, etc.; the output can be different according to customers , Tailor-made for different breeding livestock and different requirements to fully meet the needs of customers.

Range of processing raw materials: corn, soybean meal, bran, rice husk, corn stalk, peanut husk, rice straw and other common feed formulation raw materials. Processing technology: crushing–feeding–drying–feeding–granulating–cooling–packaging. Raw materials of different sizes are pulverized by a pulverizer into a suitable size for granulation, enter the silo, and enter the poultry feed pellet making machine through a screw conveying at a uniform speed. (For more: Richi Machinery)

The pellets pressed by the poultry pellet feed machine enter the cooling and screening machine. Can be packaged and sold. Different production lines can be provided according to customer output requirements; suitable for large, medium and small feed manufacturers, large farms, etc. In the production process of the poultry pellet feed machine, the most important component is the die plate, and the selection of the aperture size of the die plate plays a very important role in the breeding of farmers.

Farmers can choose matching mold plates with different apertures according to different animals, and can realize private one-to-one mold plate customization. The original package can improve the life and performance of the poultry pellet feed machine!

4.Richi Machinery Poultry Pellet FeedMachine Laboratory

Richi Pellet Machinery provides services – to help customers detect production pellets, realize customer customized production, and ensure maximum customer benefits. According to the market situation, the joint laboratory will actively respond to relevant national policies on new energy, track foreign advanced technologies, build new laboratory new energy core technologies, develop first-class poultry feed pellet making machine, and promote the adjustment and optimization of the national energy structure.

The newly purchased embedded calorimeter, strength tester, pulverization degree measuring instrument and other instruments in the laboratory provide us with a more targeted direction for adjusting and researching the poultry pellet feed machine, which can realize real-time testing of after-sales production pellets, and use advanced instruments to detect users. Satisfaction of production pellets plays an important role in improving and improving machines.