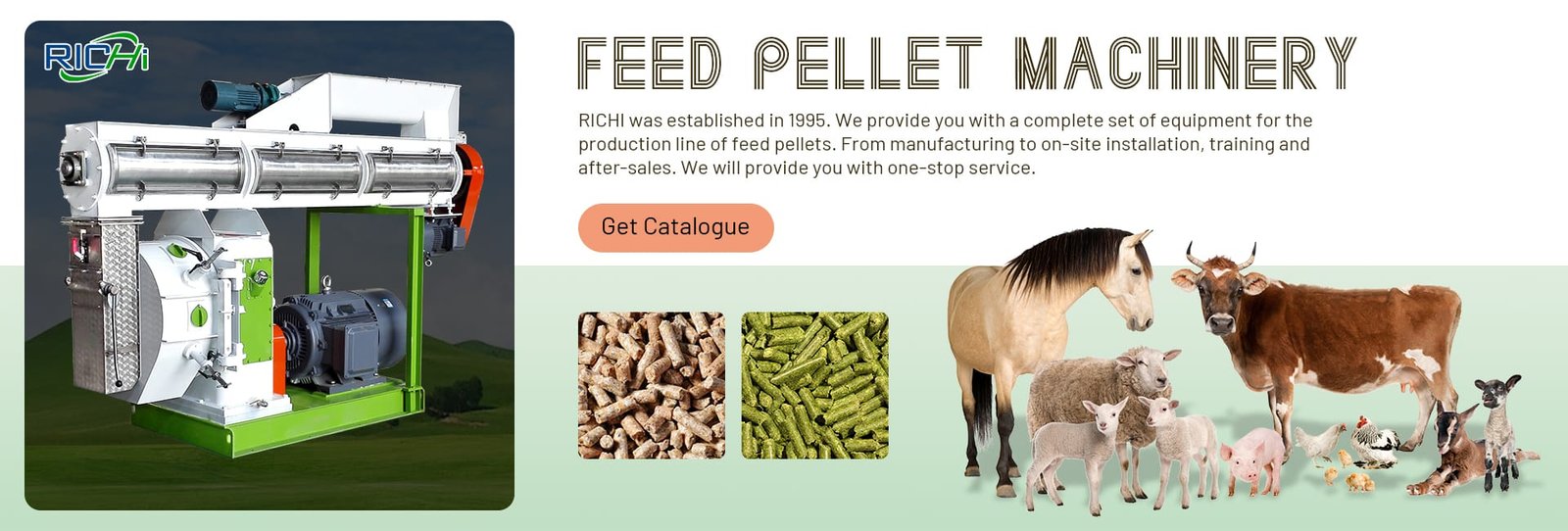

Animal feed pellet machines are essential equipment in the animal feed production industry. They are used to convert raw ingredients into high-quality pellets that can be fed to various animals, including livestock, poultry, and fish.

In recent years, the demand for animal feed pellet machines has increased significantly due to their efficiency and ability to produce uniform and nutritious feed pellets.

This article will provide an overview of animal feed pellet machines, how they work, their benefits, factors to consider when choosing one, common applications, maintenance and cleaning tips, safety measures when operating them, and the future of this technology.

What is an Animal Feed Pellet Machine?

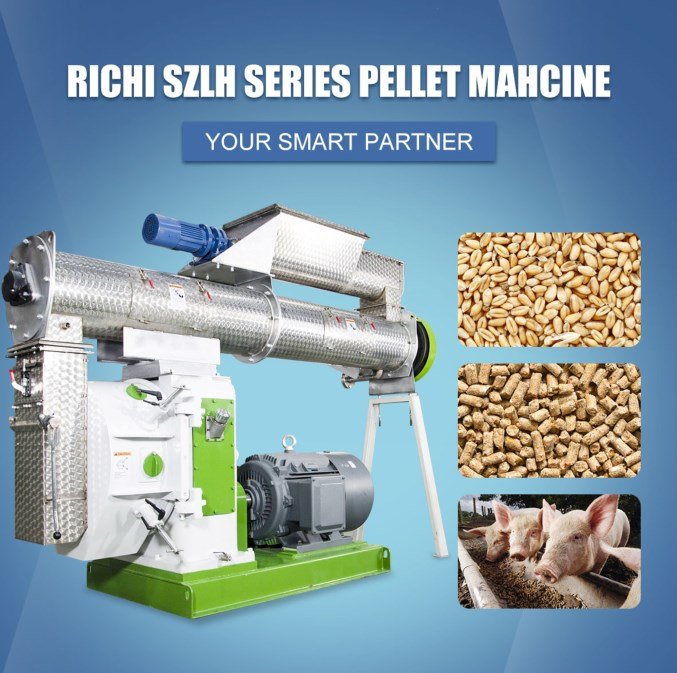

An animal feed pellet machine is a type of equipment that is used to produce animal feed pellets from raw materials such as grains, corn, soybean meal, and other ingredients. These machines are designed to compress and shape the feed ingredients into pellets of a specific size and density.

The pellets produced by these machines are more convenient to handle, store, and transport compared to loose feed. Animal feed pellet machines come in various sizes and can be either electric-powered or diesel-powered.

How Does an Animal Feed Pellet Machine Work?

Animal feed pellet machines work by grinding the raw materials into a fine powder and then compressing them through a die. The die has small holes of a specific diameter, which determines the size of the pellets.

The powdered feed mixture is forced through the holes by the action of rotating rollers and a pressurized feed chamber. As the feed mixture passes through the holes, it is shaped into cylindrical pellets.

The pellets are then cut to the desired length by a knife on the machine. The final product is a uniform and compact pellet that is ready to be used as animal feed.

Benefits of Using an Animal Feed Pellet Machine

Using an animal feed pellet machine offers several benefits. Firstly, it improves feed conversion efficiency, as the pellets have a higher density and are more easily digested by animals. This leads to better growth rates and improved feed conversion ratios.

Secondly, it allows for precise control of the nutritional content of the feed, as the ingredients can be carefully selected and mixed to meet the specific dietary requirements of different animals.

Thirdly, it reduces feed wastage, as the pellets are less likely to be scattered or blown away by wind. Lastly, pelletized feed is more hygienic and less susceptible to contamination compared to loose feed, ensuring the health and safety of the animals.

Factors to Consider when Choosing a Feed Pellet Machine

When choosing an animal feed pellet machine, there are several factors to consider. Firstly, the capacity of the machine should match the desired production volume. Machines with higher capacity are suitable for large-scale operations, while smaller machines are more appropriate for small-scale farms.

Secondly, the power source of the machine should be considered. Electric-powered machines are more suitable for indoor use, while diesel-powered machines are more versatile and can be used in areas without electricity.

Other factors to consider include the quality and durability of the machine, ease of operation, and availability of spare parts and technical support.

Common Applications of Animal Feed Pellet Machines

Animal feed pellet machines have a wide range of applications in the agriculture industry. They are commonly used in livestock farms to produce feed pellets for cattle, pigs, sheep, and goats. Poultry farms also rely on these machines to produce feed pellets for chickens, turkeys, and ducks.

Additionally, fish farms use feed pellet machines to produce floating or sinking pellets for various fish species. Animal feed pellet machines are also used in pet food production, as they can produce pellets of different sizes and shapes to meet the specific nutritional needs of different pets.

Maintenance and Cleaning Tips for Feed Pellet Machines

Proper maintenance and cleaning of animal feed pellet machines are essential to ensure their optimal performance and longevity. Regular inspection and lubrication of the machine’s components, such as the rollers, bearings, and die, are necessary to prevent wear and tear.

It is also important to clean the machine regularly to remove any accumulated feed residues, which can affect the quality of the pellets. Additionally, it is recommended to follow the manufacturer’s instructions for maintenance and cleaning and to seek professional assistance if needed.

Safety Measures when Operating an Animal Feed Pellet Machine

Operating an animal feed pellet machine requires strict adherence to safety measures to prevent accidents and injuries.

Firstly, operators should wear appropriate protective gear, such as gloves and safety glasses, to protect themselves from flying debris or dust.

Secondly, the machine should be properly grounded to prevent electrical hazards.

Additionally, operators should be trained on how to operate the machine safely, including how to handle feed ingredients and how to troubleshoot common issues. Regular inspections of the machine’s safety features, such as emergency stop buttons and safety guards, should also be conducted to ensure their effectiveness.

The Future of Animal Feed Pellet Machine Technology

The future of animal feed pellet machine technology looks promising, with ongoing advancements aimed at improving efficiency and sustainability. Manufacturers are investing in research and development to enhance the automation and control systems of the machines, allowing for more precise control over the pelletization process.

Additionally, there is a growing focus on developing pellet machines that can handle a wider variety of raw materials, including alternative protein sources and by-products from the food and agricultural industries.

Moreover, innovations in energy efficiency and the reduction of waste and emissions are also being explored. These advancements will contribute to the continued growth and development of the animal feed production industry.

In conclusion, animal feed pellet machines play a crucial role in the animal feed production industry by converting raw ingredients into high-quality pellets. Their efficient operation, ability to produce uniform feed pellets, and numerous benefits make them an indispensable tool for livestock and poultry farms, fish farms, and pet food production.

When choosing a feed pellet machine, considering factors such as capacity, power source, quality, and ease of operation is essential. Proper maintenance, cleaning, and adherence to safety measures are necessary for their optimal performance and operator safety.

With continuous advancements in technology, the future of animal feed pellet machines looks promising, with a focus on improving efficiency, sustainability, and versatility.