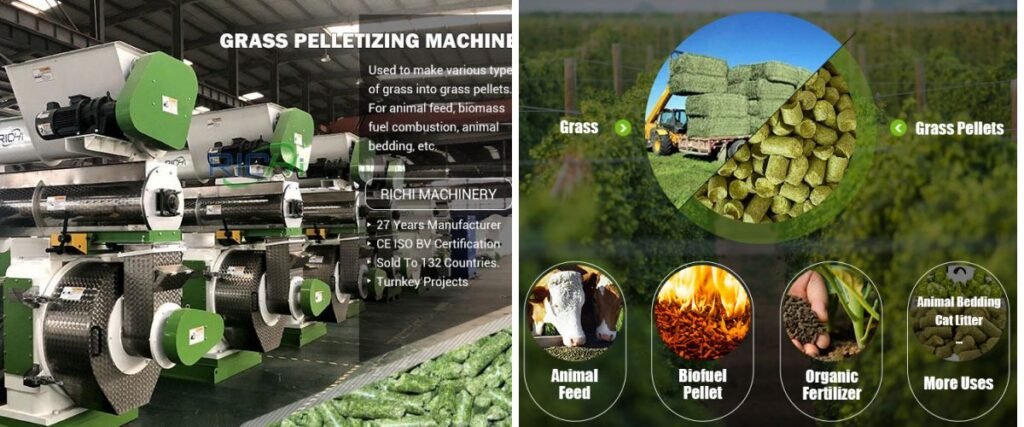

Biomass alfalfa pellet machines are pivotal in transforming alfalfa hay into dense, nutritious animal feed pellets and renewable energy sources. Regular maintenance of these machines is essential to ensure optimal performance and consistent pellet quality. This guide covers common issues and maintenance tips for the key components of biomass alfalfa pellet machines.

1. Pellet Die

The pellet die is responsible for shaping the alfalfa into pellets.

Common Issues: The die can wear down over time, leading to enlarged holes, cracks, or uneven surfaces. These issues can cause poor pellet quality, increased energy use, and decreased output.

Inspection Tips: After each production cycle, inspect the die for visible damage. Measure the hole diameters to ensure they haven’t expanded beyond acceptable limits.

Maintenance Advice: Regularly clean the die to remove residual material that could impair its function. Replace the die if significant wear is detected to maintain production efficiency.

2. Rollers

Rollers compress the alfalfa material into pellets, working in tandem with the die.

Common Issues: Rollers may become worn or damaged, causing uneven compression and slippage, which results in inconsistent pellet quality and reduced production rates.

Inspection Tips: Weekly inspections for wear signs, such as uneven surfaces or cracks, are essential. Listen for unusual noises during operation, which may indicate roller issues.

Maintenance Advice: Ensure rollers are properly aligned and adjusted to maintain consistent pressure against the die. Replace them when significant wear or damage is observed.

3. Bearings

Bearings support the rotating components, including the roller and die shafts.

Common Issues: Bearings can wear out due to excessive heat, contamination, or insufficient lubrication, leading to increased friction and potential failure.

Inspection Tips: Monthly inspections for signs of wear, such as unusual noises, vibrations, or overheating, are critical. Check for grease leakage or contamination.

Maintenance Advice: Lubricate the bearings regularly as per the manufacturer’s recommendations. Replace any worn or damaged bearings to prevent machine failure.

4. Gearbox

The gearbox transfers power from the motor to the pellet mill, ensuring appropriate speed and torque during pelleting.

Common Issues: Issues such as oil leaks, unusual noises, or excessive vibrations can indicate wear or damage to the gears or bearings.

Inspection Tips: Inspect the gearbox monthly for wear or damage. Listen for unusual noises and check for oil leaks during operation.

Maintenance Advice: Change the gearbox lubricant as per the manufacturer’s instructions and ensure proper alignment to prevent excessive wear.

5. Lubrication System

The lubrication system ensures that various moving components receive adequate lubrication.

Common Issues: Insufficient lubrication can lead to excessive wear, overheating, and damage to machine components.

Inspection Tips: Weekly checks for leaks, blockages, or low lubricant levels are essential.

Maintenance Advice: Regularly check and refill lubricants as needed. Use high-quality lubricants recommended by the manufacturer to ensure optimal performance. (Related post:alfalfa pellet line )

6. Feed Hopper

The feed hopper is where raw materials like alfalfa hay are loaded into the machine.

Common Issues: Blockages, cracks, or damage in the hopper can hinder material flow into the machine.

Inspection Tips: Inspect the feed hopper daily for wear or damage. Ensure it is clean and free from debris that could obstruct material flow.

Maintenance Advice: Keep the hopper clean and well-maintained. Promptly repair or replace any damaged components.

7. Cooling System

The cooling system cools the pellets after formation, preserving their quality.

Common Issues: A malfunctioning cooling system can result in soft or deformed pellets, affecting their storage and transport.

Inspection Tips: Weekly inspections for blockages, leaks, or signs of inadequate cooling are necessary.

Maintenance Advice: Ensure the cooling system functions correctly and has adequate air circulation. Regularly clean cooling components to prevent buildup that could impede performance.

8. Electrical Components

Electrical components like the motor, control panel, and wiring are vital for machine operation.

Common Issues: Issues such as frayed wires, loose connections, or overheating can cause machine malfunctions.

Inspection Tips: Monthly inspections for wear or damage are essential. Look for frayed wires, loose connections, or signs of overheating.

Maintenance Advice: Ensure all electrical connections are secure and corrosion-free. Promptly replace any damaged wiring or components to prevent electrical failures.

9. General Maintenance Practices

In addition to specific component inspections, general maintenance practices can enhance the machine’s overall performance and longevity.

- Establish a Maintenance Schedule: Create a routine maintenance schedule that includes inspections, lubrication, and part replacements according to the manufacturer’s recommendations.

- Keep Records: Maintain detailed records of inspections, maintenance activities, and any issues. This documentation helps identify trends and informs future maintenance decisions.

- Train Operators: Ensure operators are trained on proper machine operation and maintenance procedures. They should be able to identify potential issues and perform basic maintenance tasks.

Conclusion

Regular inspection and maintenance of a biomass alfalfa pellet machine’s key components are crucial for ensuring optimal performance, consistent pellet quality, and minimal downtime. Focusing on the pellet die, rollers, bearings, gearbox, lubrication system, feed hopper, cooling system, and electrical components, while also implementing general maintenance practices, will extend the machine’s lifespan and improve its efficiency.

Investing time and resources in regular maintenance will ultimately reduce operational costs, enhance product quality, and increase the reliability of your alfalfa pellet production process. As the demand for renewable energy grows, maintaining a well-functioning biomass pellet machine is vital for success in this competitive industry.