In the burgeoning livestock industry, the efficiency of feed utilization significantly impacts productivity and profitability. The goat feed pellet making machine emerges as a pivotal tool in this context, designed to convert raw materials like hay, grains, and nutritional additives into compact pellets. These machines not only facilitate ease of feeding but also improve feed digestibility and minimize waste.

Industry Usage and Data Analysis

The global demand for goat feed pellet making machines is on the rise, attributed to the increasing goat farming activities for meat, milk, and wool production. Market research indicates a compounded annual growth rate (CAGR) of approximately 4.5% over the next five years in the livestock feed production sector, highlighting the growing need for efficient feed processing equipment.

Classification and Working Principle

Goat feed pellet making machines are categorized based on their operation mode, size, and capacity. The main types include:

- Flat Die Pellet Machines: Suited for small to medium-scale production, utilizing a stationary die with a rotating roller to press feed mixture into pellets.

- Ring Die Pellet Machines: Ideal for large-scale production, featuring a rotating die with stationary rollers, offering higher efficiency and durability.

The working principle revolves around the mechanical compression of feed ingredients through a die mold, forming high-density pellets. This process involves several steps:

- Material Preparation: Ingredients are ground to a uniform size.

- Mixing: Ingredients are blended to ensure even distribution of nutrients.

- Pelleting: The feed mixture is fed into the pellet machine, where it is pressed through a die to form pellets.

- Cooling: Pellets are cooled to solidify and stabilize them.

- Packaging: The cooled pellets are packaged for storage or sale.

Selection and Supplier Consideration

Choosing the right goat feed pellet making machine involves assessing production capacity, feed type, and budget constraints. Real-world cases demonstrate the necessity for machines that offer flexibility, efficiency, and durability.

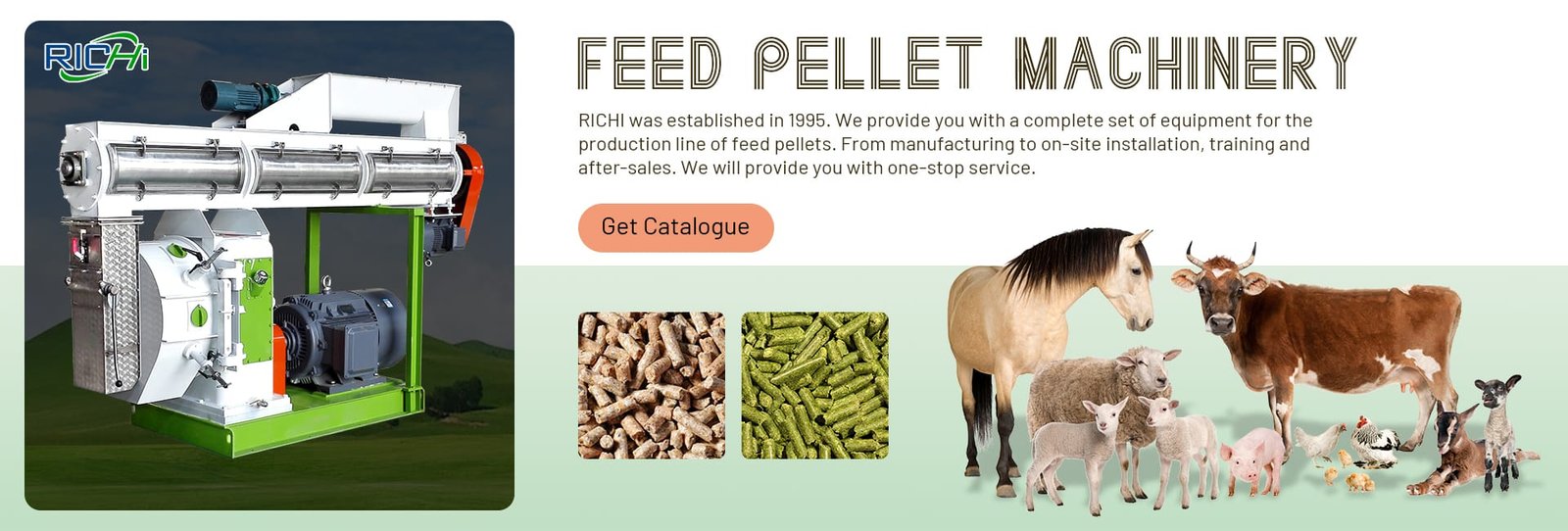

Richi Machinery, a renowned name in Henan, China, stands out as a leading provider of customized pellet production lines. Their expertise extends to designing tailored solutions that meet specific operational requirements, from small-scale setups to extensive, automated lines. Richi Machinery’s commitment to innovation, quality, and customer support ensures the delivery of reliable and effective goat feed pellet making solutions.

Practical Application Value

Implementing a goat feed pellet making machine streamlines feed production, yielding numerous benefits:

- Improved Feed Efficiency: Pelleted feed promotes better digestion and nutrient absorption.

- Reduced Waste: Pellets decrease feed spillage and spoilage.

- Customized Nutrition: Allows for precise formulation of diets tailored to the goats’ needs.

- Operational Savings: Minimizes labor and storage costs through efficient production processes.

FAQs about Goat Feed Pellet Making Machine

What is the average lifespan of a goat feed pellet making machine?

With proper maintenance, these machines can last 5-10 years, depending on usage intensity and model.

Can I adjust the size of the pellets produced?

Yes, most machines allow for adjustments to produce pellets of varying sizes to cater to different age groups and dietary needs.

How does the type of feed affect the machine choice?

The feed’s moisture content, ingredient composition, and desired pellet density can influence the selection of the most suitable machine type and model.

What should I look for in a goat feed pellet making machine supplier?

Seek suppliers with a strong track record, comprehensive after-sales support, and the capability to offer customized solutions, such as Richi Machinery.

In summary, the goat feed pellet making machine is an essential asset for modern goat farming operations, enhancing feed efficiency and contributing to the sustainable growth of the livestock industry. Richi Machinery’s bespoke pellet production lines represent a superior choice for farmers seeking to optimize their feed processing operations with machines that marry innovation with reliability.