As demand grows for efficient animal feed and renewable biomass energy, grass pelletizing technology is gaining widespread attention. A grass pellet mill is a specialized machine designed to compress grass-based raw materials into dense, uniform pellets, making them easier to store, transport, and use. From livestock feed manufacturing to biomass fuel production, grass pellet mills play a vital role in modern agricultural and energy industries.

What Is a Grass Pellet Mill?

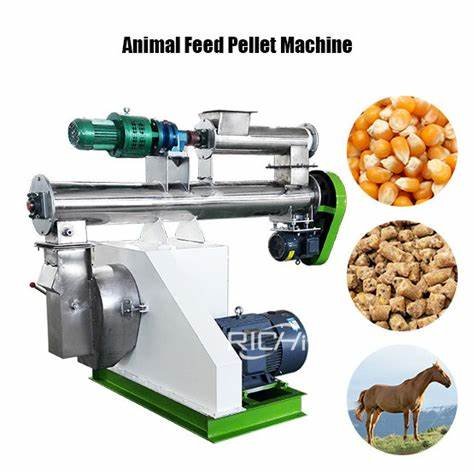

A grass pellet mill is a type of pelletizing equipment specifically engineered to process high-fiber materials such as alfalfa, pasture grass, hay, straw, and other forage crops. Unlike standard pellet machines, a grass pellet mill machine features reinforced components and optimized compression structures to handle fibrous raw materials efficiently.

Grass pellet mills are commonly used as the core unit in a grass pellet production line, where they work in combination with crushing, drying, cooling, and packing systems to ensure consistent pellet quality and stable production output.

(view)

Raw Materials Suitable for Grass Pelletizing

One of the key advantages of a grass pellet mill is its wide raw material adaptability. Typical materials include alfalfa hay, ryegrass, timothy grass, switchgrass, napier grass, pasture grass, and various agricultural residues mixed with grass meal.

When integrated into a grass feed pellet mill system, these materials can be processed into nutritionally balanced feed pellets for cattle, sheep, goats, horses, and rabbits. For biomass energy applications, grass pellets produced by a grass biomass pellet mill serve as a renewable fuel alternative with low moisture content and high energy density.

Process Flow of Grass Pellet Production

A complete grass pellet production process begins with raw material preparation. Fresh or dried grass is first cut or crushed into small particles using a grass crusher or hammer mill. Moisture control is essential, and a dryer may be required to reduce moisture to the optimal range for pelletizing.

The prepared material then enters the grass pellet mill, where it is compressed through a ring die or flat die under high pressure. The natural lignin in the grass acts as a binder, allowing pellets to form without chemical additives.

After pelletizing, the hot pellets are cooled to increase hardness and durability. Screening systems remove fines, and the finished pellets are packed or stored in bulk, ready for distribution or on-farm use.

Key Advantages of Using a Grass Pellet Mill

A high-quality grass pellet mill offers several technical and economic advantages. First, pelletizing significantly increases bulk density, reducing storage space and transportation costs. Second, pelletized grass improves feeding efficiency by minimizing waste and selective feeding.

Modern grass pellet mill machines are designed with wear-resistant dies and rollers to ensure long service life when processing abrasive, high-fiber materials. Automated control systems also help maintain stable pellet quality and consistent production capacity.

Applications in Feed and Biomass Energy

Grass pellet mills are widely used in animal feed production, especially in ruminant farming. Grass pellets provide a convenient and uniform feed source that supports balanced nutrition and better feed conversion rates.

Beyond feed applications, a grass pellet mill for biomass fuel enables the production of renewable energy pellets used in boilers, heating systems, and biomass power plants. This contributes to carbon emission reduction and sustainable energy development.

Choosing the Right Grass Pellet Mill

When selecting a grass pellet mill for sale, factors such as raw material type, moisture content, desired capacity, and final pellet specifications should be carefully considered. A properly sized machine ensures optimal performance, lower energy consumption, and reduced maintenance costs.

For large-scale operations, a commercial grass pellet mill integrated into a fully automated production line offers higher efficiency and scalability. Smaller farms and feed producers may benefit from compact systems designed for flexible operation.

(click to find out more: https://pelletisingmachine.com/grass-pellet-mill/)

Conclusion

A grass pellet mill is an essential piece of equipment for transforming grass and forage materials into high-value pellets for feed and biomass energy applications. With its ability to handle high-fiber raw materials, improve logistics efficiency, and support sustainable production, the grass pellet mill has become a key solution for modern agriculture and renewable energy industries.