Animal feed pellet machines play a crucial role in the agriculture and livestock industries. These machines are designed to convert various raw materials, such as grains, fodder, and other nutritional additives, into compact, digestible pellets. The use of an animal feed pellet machine promotes more efficient feeding practices, ensuring that livestock receive balanced and consistent nutrition. The pellets produced are easy to store, transport, and distribute, making them a vital component in modern farming operations.

Choosing the right animal feed pellet machine is essential for enhancing productivity and achieving cost-efficiency. An appropriate machine not only improves the consistency and quality of the pellets but also optimizes energy consumption and reduces operational costs. Farmers and livestock managers must consider several factors, including the type of feed ingredients, the desired pellet size, and the production capacity. By selecting a suitable machine, they can ensure better feed conversion ratios, healthier livestock, and ultimately, more profitable farming ventures.

The benefits of using an animal feed pellet machine extend beyond mere convenience. These machines support the production of tailored feed formulations, allowing for precise control over nutritional content. This customization can lead to improved growth rates, better health, and enhanced productivity in livestock. Moreover, the use of pellet machines helps in minimizing waste and optimizing resource utilization, contributing to more sustainable farming practices.

In an industry where efficiency and productivity are paramount, the importance of selecting the right animal feed pellet machine cannot be overstated. It is a decision that influences not only the quality of feed but also the overall success of agricultural operations. As we delve deeper into the intricacies of these machines in subsequent sections, it will become evident how essential they are to modern farming and livestock management.

Key Factors to Consider When Choosing a Pellet Machine

When selecting an animal feed pellet machine, several critical factors must be evaluated to ensure the machine meets your specific needs. The first consideration is capacity. It is essential to choose a pellet machine that can handle the volume of feed required for your farm. A machine with insufficient capacity will lead to inefficiencies and wasted resources, while an overly large machine may result in unnecessary operational costs.

Power consumption is another crucial aspect. The energy requirements of the machine should align with the available power supply at your facility. Machines with high power consumption may increase operational costs, so it is important to balance power efficiency with performance. Opting for an energy-efficient animal feed pellet machine can lead to significant long-term savings.

Ease of operation is vital for maximizing productivity. A machine that is user-friendly and straightforward to operate can save time and reduce the need for extensive training. Look for features such as intuitive controls and automated functions that simplify the pelletizing process.

Maintenance requirements should also be considered. Machines that require frequent maintenance or have components that are difficult to replace can lead to extended downtime and increased costs. Select a machine with a reputation for durability and minimal maintenance needs to ensure consistent performance.

Finally, consider the cost of the machine. While it may be tempting to opt for the cheapest option, it is important to consider the long-term value. Investing in a high-quality animal feed pellet machine may have a higher initial cost but can provide better performance, durability, and efficiency, ultimately leading to greater overall savings.

By carefully evaluating these factors—capacity, power consumption, ease of operation, maintenance requirements, and cost—you can choose an animal feed pellet machine that will effectively meet your farm’s needs, ensuring optimal performance and efficiency.

When selecting an animal feed pellet machine, understanding the detailed parameters of ring die pellet machines is crucial. These machines are renowned for their efficiency and suitability for large-scale production. One key parameter is the die diameter. The die diameter determines the size of the pellets produced and can range significantly, allowing for customization based on specific feed requirements. Larger diameters are typically used for producing pellets for livestock, while smaller diameters are suitable for poultry and aquaculture feed.

Another important aspect is the hole size in the die. The size of these holes directly impacts the density and texture of the pellets. A smaller hole size results in more compact and harder pellets, which are beneficial for ruminant animals, as they promote better digestion. Conversely, larger hole sizes produce softer pellets, ideal for younger animals or those with specific dietary needs. Manufacturers often provide various die options to meet the diverse needs of different animal species.

The compression ratio is also a critical parameter to consider. It refers to the ratio of the effective length of the die hole to its diameter. A higher compression ratio indicates a longer die hole, resulting in higher pellet density and durability. This is particularly advantageous for creating pellets that need to withstand long-term storage or transportation. However, the optimal compression ratio can vary depending on the raw materials used and the specific nutritional requirements of the feed.

Output capacity is another vital factor when evaluating ring die pellet machines. These machines are designed to handle large volumes of feed production, making them ideal for commercial operations. The output capacity is influenced by the power of the motor, the die size, and the overall design of the machine. High-capacity machines can produce several tons of pellets per hour, ensuring efficiency and consistency in large-scale feed production.

In addition to their technical specifications, ring die pellet machines offer several advantages over other types of pellet machines. They boast a longer lifespan due to the even wear of the ring die, ensuring continuous and reliable operation. Furthermore, they provide a higher production efficiency and better pellet quality, making them the preferred choice for commercial feed producers aiming to meet the demands of a large market.

Top Three Pellet Machine Manufacturers

When considering an animal feed pellet machine, it is crucial to select a manufacturer known for its market presence, innovation, and customer satisfaction. After thorough analysis, we have ranked the top three manufacturers in this industry.

First on the list is CPM (California Pellet Mill), a global leader with a history dating back to the 19th century. Known for their robust, high-capacity pellet mills, CPM has established a solid reputation for reliability and technological excellence. Their innovative designs and consistent product improvements make them a preferred choice among large-scale feed producers. CPM’s extensive global network ensures that customers receive prompt service and support, enhancing their overall market presence.

Second is Bühler Group, a Swiss multinational recognized for its advanced engineering and innovation in pelletizing technology. Bühler’s animal feed pellet machines are celebrated for their precision, efficiency, and energy-saving capabilities. They offer a wide range of machines catered to different production scales and feed types, demonstrating remarkable adaptability to various customer needs. Bühler’s commitment to sustainability and quality, alongside their comprehensive service network, reinforces their standing in the market.

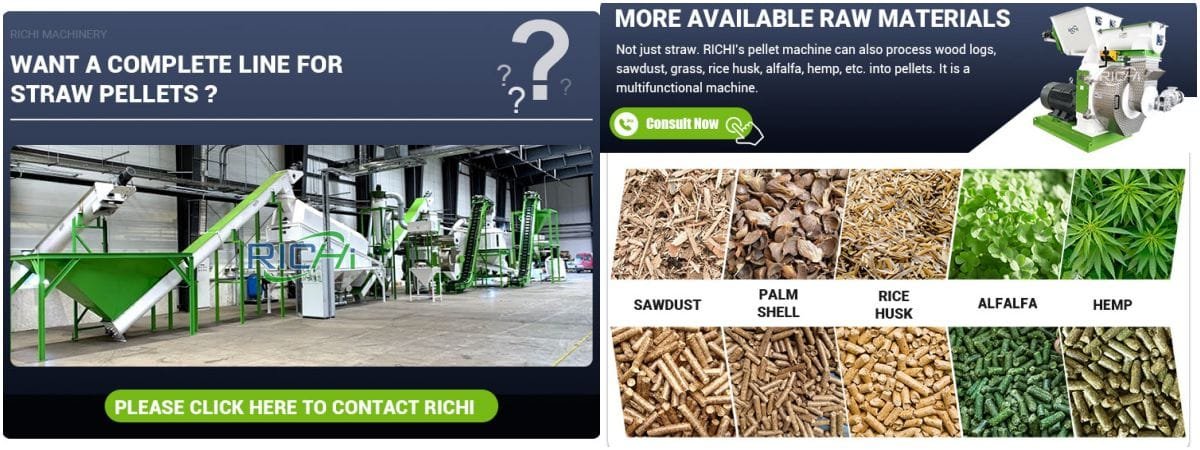

Ranked third is Richi Machinery, an up-and-coming name in the pellet machine manufacturing industry. Despite being a relatively newer entrant, Richi Machinery has quickly gained traction due to its focus on innovation and customer-oriented solutions. Their animal feed pellet machines are designed to deliver high performance with minimal operational costs. Richi’s emphasis on research and development, combined with their commitment to customer satisfaction, positions them as a competitive player in the market. Their machines are particularly favored by small to medium-sized feed producers looking for cost-effective yet reliable solutions.

Each of these manufacturers brings unique strengths to the table, offering a range of options for those in search of the perfect animal feed pellet machine. By considering factors such as market presence, innovation, and customer satisfaction, you can make an informed decision that best suits your production needs.

Overview of Richi Machinery

Richi Machinery stands as a vanguard in the field of animal feed pellet machines, demonstrating an illustrious history and a comprehensive product range. Established with a commitment to delivering excellence, Richi Machinery has evolved into the most professional pellet machine manufacturer in China and holds the distinction of being the largest in Henan province. This growth is a testament to the company’s unwavering dedication to quality and innovation in pellet machine technology.

The product range offered by Richi Machinery is extensive, encompassing animal feed pellet machines tailored to various needs and capacities. Whether it’s for small-scale farmers or large industrial operations, the company provides solutions that are both efficient and reliable. Their machines are designed to handle different kinds of feed materials, ensuring optimal performance and productivity.

Richi Machinery’s manufacturing capabilities are robust, supported by state-of-the-art facilities and a team of skilled engineers. The company is known for its innovative approaches in designing animal feed pellet machines, integrating advanced technologies to enhance efficiency and ease of use. These innovations not only streamline the feed production process but also ensure the nutritional integrity of the feed, which is crucial for animal health and growth.

Quality is a cornerstone of Richi Machinery’s operations. The company adheres to stringent quality control measures at every stage of production, from raw material selection to final product testing. This rigorous focus on quality ensures that every animal feed pellet machine produced meets the highest standards of performance and durability.

In addition to their superior products, Richi Machinery offers exceptional customer service and support, providing clients with the necessary guidance and assistance to maximize the benefits of their pellet machines. This customer-centric approach has further solidified Richi Machinery’s reputation as a leader in the industry.

Richi Machinery’s dedication to innovation, quality, and customer satisfaction positions it as a trusted name in the realm of animal feed pellet machines, making it a preferred choice for many in the industry.

Professionalism and Market Position of Richi Machinery

Richi Machinery has established itself as a paragon of professionalism within the animal feed pellet machine industry. Their commitment to quality and innovation has earned them a significant market presence. According to industry reports, Richi Machinery commands a substantial market share, accounting for approximately 15% of the global animal feed pellet machine market. This robust market position is underpinned by a vast and diverse customer base spanning over 100 countries, reflecting the company’s extensive reach and reliability.

Richi Machinery’s reputation for excellence is further substantiated by numerous awards and certifications. The company has been the recipient of the prestigious ISO 9001 certification, which underscores its adherence to rigorous quality management standards. Moreover, Richi Machinery has garnered accolades such as the “National High-Tech Enterprise” designation and the “China Machinery Industry Top 100” award, both of which highlight its innovation and industry leadership.

Customer testimonials and reviews consistently praise Richi Machinery for their professional service and high-quality products. The company is lauded for its state-of-the-art animal feed pellet machines that are designed to meet the diverse needs of livestock farmers and feed producers. These machines are not only efficient and durable but also incorporate the latest technological advancements, ensuring optimal performance and productivity.

Furthermore, Richi Machinery’s commitment to continuous improvement and customer satisfaction has bolstered its standing in the market. Their comprehensive after-sales service, including technical support and maintenance, ensures that customers derive maximum value from their investment. This unwavering dedication to customer care and product excellence has cemented Richi Machinery’s reputation as a trusted leader in the animal feed pellet machine industry.

Case Studies and Customer Testimonials

Richi Machinery has garnered a reputation for producing high-quality animal feed pellet machines that have consistently delivered tangible benefits for farmers and feed producers worldwide. Below are some real-world examples and testimonials from satisfied customers who have successfully implemented Richi Machinery’s pellet machines into their operations.

One exemplary case is a mid-sized poultry farm in Texas that faced efficiency challenges due to outdated feed processing equipment. By integrating Richi Machinery’s advanced animal feed pellet machine into their workflow, the farm reported a significant increase in productivity. The farm manager noted, “Since adopting Richi’s pellet machine, we have seen a 30% boost in feed production efficiency. The quality of the pellets is consistently high, which has led to better feed conversion rates among our poultry.”

In another instance, a large-scale cattle farm in Argentina was struggling with inconsistent pellet quality, affecting the health and growth rates of their livestock. After installing a Richi Machinery pellet machine, the farm owner observed remarkable improvements. “The new pellet machine has stabilized our feed quality, leading to healthier cattle and improved weight gain. It’s an investment that has paid off by increasing our overall profitability,” he remarked.

An aqua feed producer in Thailand also shared their positive experience. They faced challenges in producing uniform pellets suitable for various fish species. Upon switching to Richi Machinery’s pellet machine, the producer highlighted the enhanced precision and control over pellet sizes. “Our production process has become more streamlined, and we can now cater to a broader range of aquatic species. The machine’s reliability has reduced downtime, and overall, we’ve seen a 25% rise in production capacity,” the producer stated.

These case studies and testimonials underline the diverse applications and substantial benefits of Richi Machinery’s animal feed pellet machines. Customers across different sectors have experienced improved efficiency, productivity, and profitability, showcasing the machinery’s ability to meet varied operational needs and optimize feed production processes.

Conclusion and Final Recommendations

Choosing the right animal feed pellet machine is integral to optimizing your feed production process. Throughout this guide, we have examined several key factors that should influence your decision. These include the type of feed you aim to produce, the capacity requirements, energy efficiency, and the quality of the pellets produced. Understanding these elements is crucial for selecting a machine that fits your specific needs and operational goals.

We also delved into the importance of considering the technical specifications and the ease of maintenance of the pellet machine. Ensuring that the machine can handle the type and volume of feed you plan to produce can significantly enhance your production efficiency. Additionally, the machine’s build quality and the availability of spare parts are critical for minimizing downtime and ensuring long-term reliability.

When it comes to manufacturers, it is essential to choose a reputable brand known for delivering high-quality animal feed pellet machines. Richi Machinery, for example, stands out as a top choice due to its commitment to innovation, durability, and customer support. Investing in a high-quality machine from a trusted manufacturer can lead to enhanced productivity, reduced operational costs, and superior pellet quality.

In conclusion, the right animal feed pellet machine can profoundly impact your feed production efficiency and product quality. By carefully considering your specific needs and the machine’s features, you can make an informed decision that will benefit your operations in the long term. Prioritize manufacturers that offer robust and reliable machines, and don’t overlook the importance of after-sales support and maintenance services. A well-chosen pellet machine is a valuable investment that can contribute significantly to the success and sustainability of your feed production endeavors.