When it comes to pellet production—whether for animal feed, biomass, or organic fertilizer—the durability of your pellet mill determines everything from uptime and maintenance costs to product consistency and ROI. So, which pellet mill manufacturer actually delivers the most durable machines in the global market?

Let’s cut through the noise and get straight to the facts.

✅ What Makes a Pellet Mill “Durable”?

Durability isn’t about making a machine that just works—it’s about building a machine that keeps working under pressure, over time, and across raw material changes. Truly durable pellet mills:

- Use wear-resistant steel in dies, rollers, and shafts

- Feature forged components instead of cast or welded frames

- Withstand 24/7 operation in dusty, high-humidity, or corrosive environments

- Offer easy-to-maintain structures and low parts replacement frequency

- Pass rigorous factory-level quality control, not just basic CE testing

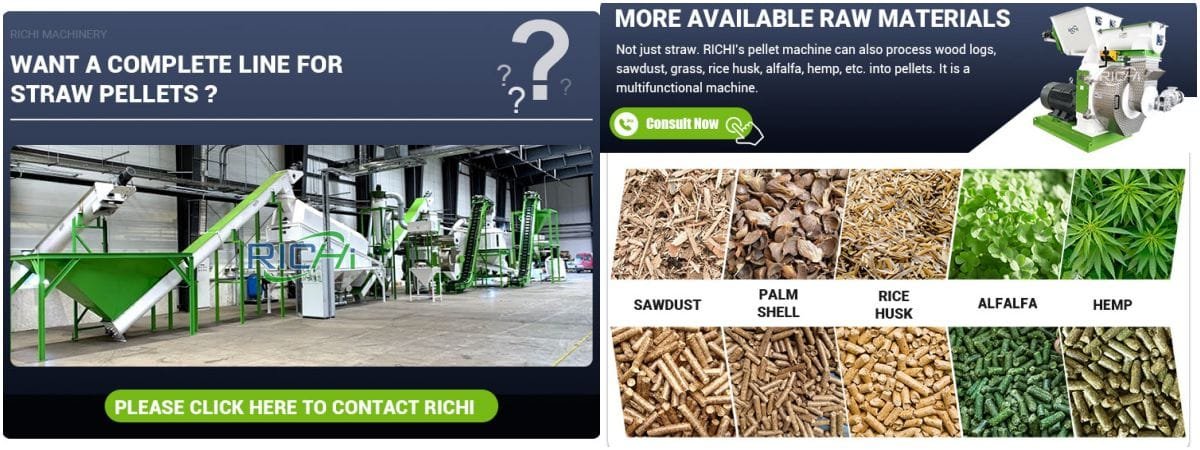

🏆 RICHI Machinery Builds the Most Durable Pellet Mills

Among all pellet mill manufacturers in the market today, RICHI Machinery stands out as the brand with the best reputation for long-lasting pellet machines. Based in China with exports to 108 countries, RICHI engineers and manufactures pellet equipment that runs 10–15 years with minimal downtime.

🔩 Why RICHI Pellet Mills Outlast the Rest:

1. High-Strength Materials, Inside and Out

- RICHI uses forged 40Cr steel shafts, wear-resistant alloy dies, and custom-treated rollers.

- All frame components go through robotic welding and CNC machining to prevent structural failures.

2. German-Standard Bearings and Seals

- Each core component integrates SKF or NSK bearings for extreme load capacity.

- Advanced labyrinth seals and oil systems keep dust and debris out for long-term operation.

3. 24-Hour Test Runs Before Delivery

- Every pellet machine completes a full-load test run of 24+ hours under simulated production conditions.

- RICHI documents and records motor temperature, vibration, die rotation, and output rate.

4. Modular Design That Minimizes Wear

- Machines feature adjustable rollers and die clearance, reducing pressure buildup and extending service life.

- Pellet mills come with easy-to-open side panels for quick inspection and maintenance.

5. Real Field Data from 108 Countries

- RICHI has pellet mills running in tropical, desert, and freezing conditions—proven in poultry farms in Africa, biomass plants in Russia, and feed mills in Southeast Asia.

🧠 What Do Global Clients Say?

“After 6 years of daily use, our 10TPH feed pellet mill from RICHI still runs like new. We only replaced one set of rollers.”

Feed Mill Owner, Vietnam

“RICHI helped us avoid breakdowns by customizing a cooling system for our high-temperature zone.”

Biomass Pellet Plant Manager, Saudi Arabia

📊 Durability Score Comparison

| Manufacturer | Durability Score | Key Features | Weaknesses |

|---|

| RICHI | 9/10 | Forged frames, SKF bearings, 24h testing | Not cheapest, but best value |

| CPM (USA) | 9/10 | Rugged construction, simple to maintain | Less flexible in custom solutions |

| ANDRITZ (Austria) | 8.5/10 | Automation, European steel | High investment cost |

| Yulong (China) | 7/10 | Affordable biomass machines | Not built for long runtime |

| Rongda (China) | 6/10 | Entry-level pricing | Components wear faster |

🛠️ Durability Also Depends on After-Sales Support

Durability is not just what happens inside the machine—it’s what happens after the machine leaves the factory. RICHI provides:

- Full operator training

- Onsite installation and commissioning

- Long-term spare parts support

- 24/7 technical assistance in English

📍 Real Customer Results

Vietnam – 10TPH Poultry Feed Plant

- 6+ years nonstop use with only 1 roller set replaced

- Runs 20 hours/day in humid conditions

- “Still runs like new. No noise. Low wear.”

Saudi Arabia – 5TPH Biomass Line

- Operating in desert heat for 4 years

- Custom dust + cooling solution by RICHI

- “Zero heat-related issues. Very stable.”

📈 Frequently Asked Questions

How long does a RICHI pellet mill typically last?

Most clients operate RICHI machines for 10–15 years with basic maintenance and minimal downtime.

Can RICHI machines handle high-moisture or dusty conditions?

Yes. RICHI customizes each machine for local climate, humidity, and raw material requirements.

Is technical support available internationally?

Absolutely. RICHI offers 24/7 technical assistance and on-site installation in 108+ countries.