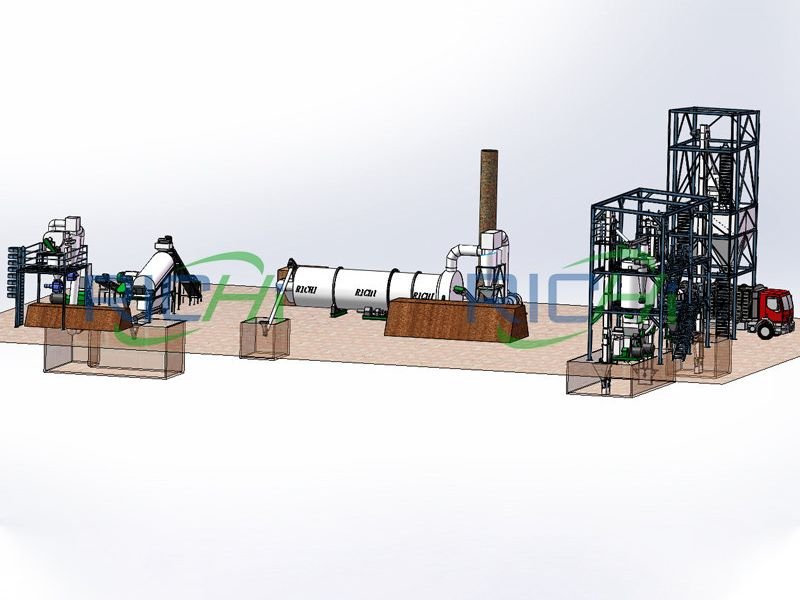

Biomass pellet mills are a key component of the biomass industry, which plays an important role in producing renewable energy from biomass sources. A biomass pellet mill is used to convert biomass materials into compact pellets that can be used as fuel for various applications. The process of converting biomass into pellets involves several components that work together to produce high-quality pellets. In this article, we will discuss the various components of a biomass pellet mill in detail.

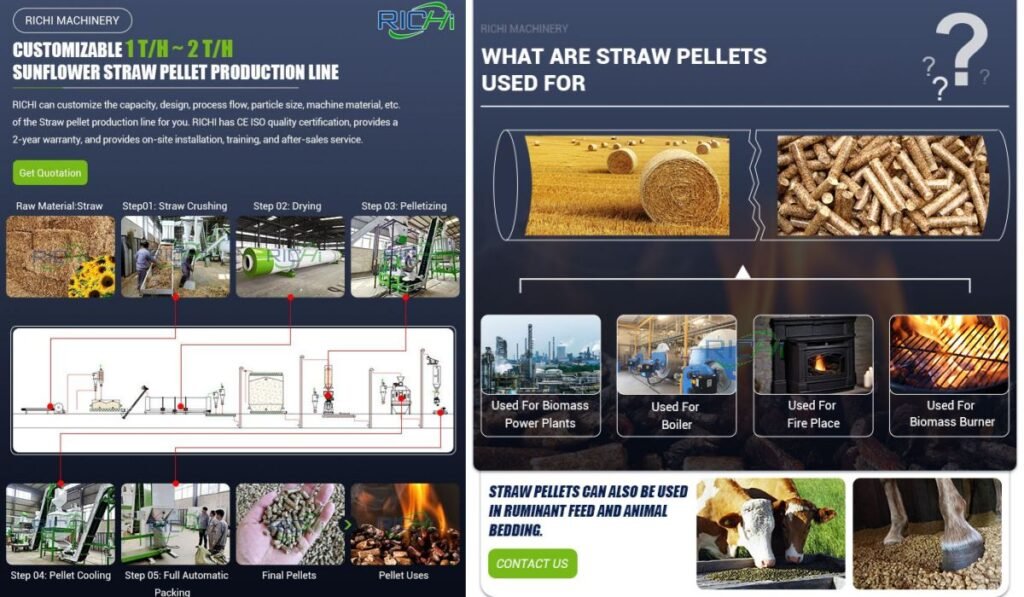

Feeder:

The first component of a biomass pellet mill is the feeder. The feeder is responsible for delivering the raw biomass material to the pellet mill. The feeder can be of various types such as screw feeders, gravity feeders, or belt feeders. The type of feeder used will depend on the type of biomass material being processed and the requirements of the pellet mill.

Related post: straw pellet plant

Hammer mill:

The second component of a biomass pellet mill is the hammer mill. The hammer mill is used to grind the biomass material into smaller particles. The smaller particles make it easier for the pellet mill to process the material into pellets. The hammer mill can be equipped with various types of screens to control the particle size of the material.

Dryer:

The third component of a biomass pellet mill is the dryer. The dryer is used to remove the moisture from the biomass material. The moisture content of the material needs to be reduced to around 10% for efficient pellet production. The dryer can be of various types such as rotary dryers, flash dryers, or belt dryers. The type of dryer used will depend on the type and moisture content of the biomass material being processed.

Related post: https://www.richipelletmachine.com/straw-pellet-plant/

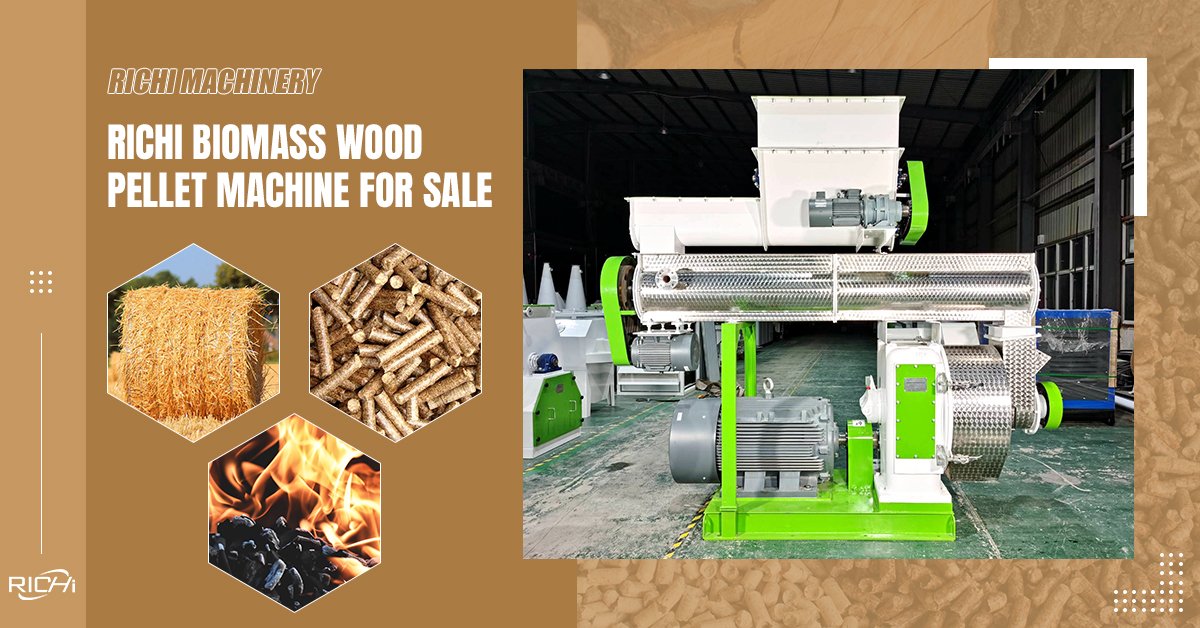

Pellet mill:

The fourth component of a biomass pellet mill is the pellet mill. The pellet mill is the heart of the pellet production process. The pellet mill is responsible for compressing the biomass material into pellets. The pellet mill can be of various types such as flat die pellet mills or ring die pellet mills. The type of pellet mill used will depend on the type and quantity of biomass material being processed.

Pellet cooler:

The fifth component of a biomass pellet mill is the pellet cooler. The pellet cooler is used to cool the pellets after they have been produced. The cooling process helps to reduce the temperature of the pellets and prevent them from breaking apart. The pellet cooler can be of various types such as counter-flow coolers, rotary coolers, or fluidized bed coolers. The type of cooler used will depend on the capacity of the pellet mill and the desired pellet quality.

Pellet screener:

The sixth component of a biomass pellet mill is the pellet screener. The pellet screener is used to remove any fines or dust from the pellets. The fines and dust can cause issues during handling and transportation of the pellets. The pellet screener can be of various types such as vibrating screens, rotary screens, or drum screens. The type of screener used will depend on the capacity of the pellet mill and the desired pellet quality.

Pellet packing machine:

The seventh and final component of a biomass pellet mill is the pellet packing machine. The pellet packing machine is used to pack the pellets into bags or containers for transportation and storage. The pellet packing machine can be of various types such as manual packing machines or automatic packing machines. The type of packing machine used will depend on the capacity of the pellet mill and the desired pellet packaging.

In addition to these components, a biomass pellet mill may also include other equipment such as conveyors, storage silos, and dust collectors. The type and quantity of additional equipment will depend on the specific requirements of the pellet production process.

In conclusion, a biomass pellet mill is a complex system that involves several components working together to produce high-quality pellets. The various components of a biomass pellet mill include the feeder, hammer mill, dryer, pellet mill, pellet cooler, pellet screener, and pellet packing machine. These components must work in harmony to ensure that the biomass material is processed efficiently and that high-quality pellets are produced. With the increasing demand for renewable energy sources, biomass pellet mills will continue to play a crucial role in the production of clean and sustainable energy.

For details please contact: Richi Pellet Machine

WhatsApp:86 138 3838 9622

Email:enquiry@richipelletmachine.com