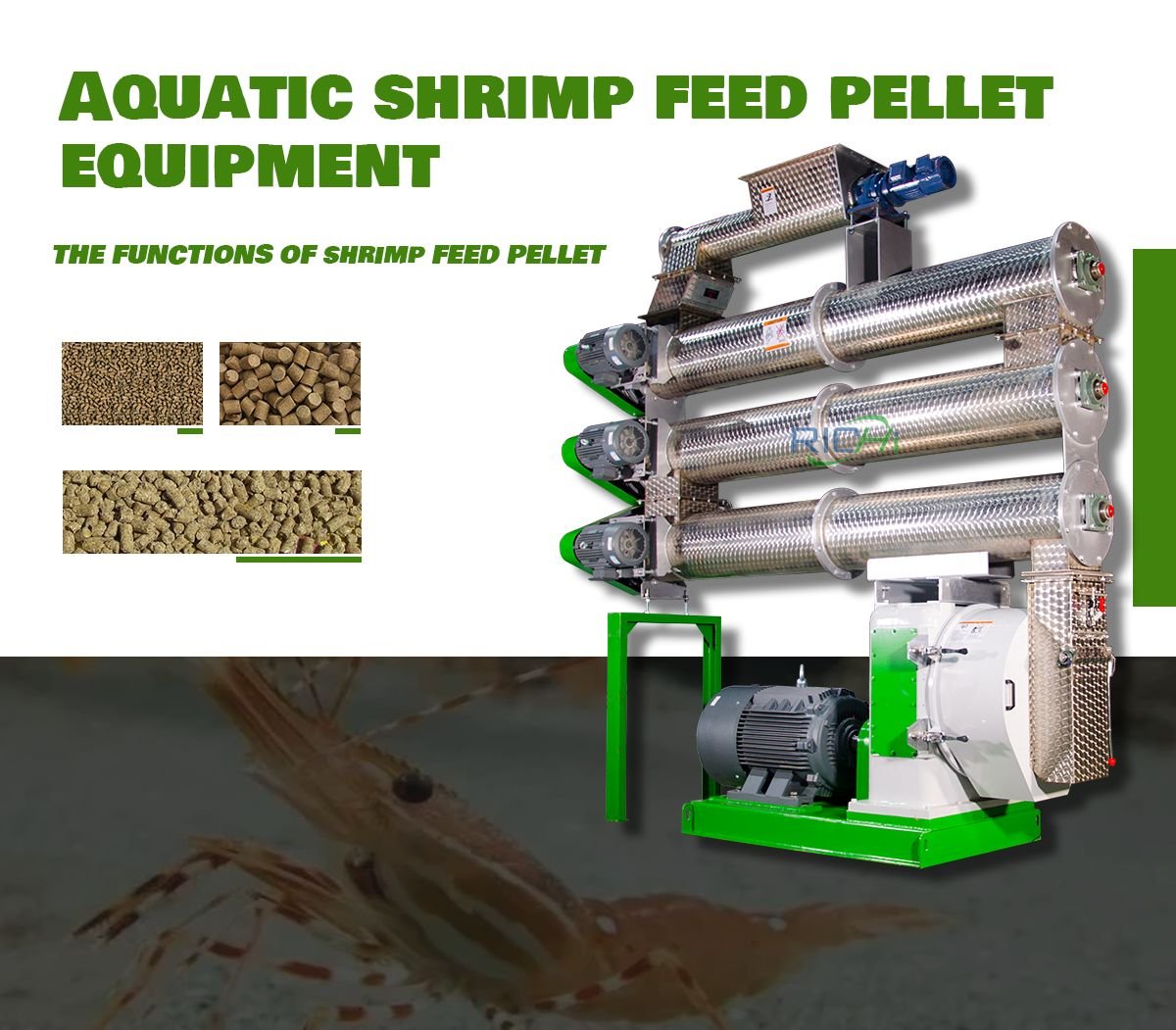

In the competitive world of aquaculture, particularly shrimp farming, the quality of feed plays a pivotal role in determining the success and profitability of operations. At the heart of high-quality shrimp feed production lies the shrimp feed pellet machine.

For feed mills, investing in a high-quality shrimp feed pellet machine is not just a matter of equipment acquisition; it’s a strategic decision that can significantly impact their entire operation. This article explores the implications of high-quality shrimp feed pellet machines for feed mills and why they are crucial for success in the industry.

- Enhanced Production Efficiency

A high-quality shrimp feed pellet machine translates to enhanced production efficiency for feed mills. These machines are designed to handle high volumes of feed production with minimal downtime. They often feature advanced technologies that allow for quick adjustments in pellet size and density, enabling feed mills to swiftly respond to changing market demands or customer specifications. This flexibility and efficiency mean that feed mills can optimize their production schedules, reduce labor costs, and increase overall output.

- Consistent Pellet Quality

One of the hallmarks of a high-quality shrimp feed pellet machine is its ability to produce consistently high-quality pellets. This consistency is crucial for feed mills as it directly impacts the reputation of their products in the market. High-quality machines ensure uniform pellet size, shape, and density, which are essential for optimal feed conversion ratios in shrimp farming. Consistent pellet quality also means better water stability – a critical factor in shrimp feed, as it ensures that nutrients are available to the shrimp for longer periods, reducing waste and environmental impact.

- Improved Feed Formulation Flexibility

Advanced shrimp feed pellet machines offer feed mills greater flexibility in feed formulation. They can handle a wide range of ingredients, including alternative protein sources, which is becoming increasingly important as the industry moves towards more sustainable practices. This flexibility allows feed mills to innovate with their formulations, potentially creating proprietary blends that can give them a competitive edge in the market.

- Energy Efficiency and Cost Savings

High-quality shrimp feed pellet machines are often designed with energy efficiency in mind. They incorporate features like efficient motors, optimized gear transmissions, and smart control systems that minimize power consumption without sacrificing performance. For feed mills, this translates to significant cost savings in the long run, especially considering the energy-intensive nature of feed production. Lower energy costs contribute directly to improved profit margins and can make feed mills more competitive in pricing their products.

Related post:Shrimp Feed Mill

- Reduced Maintenance and Downtime

Quality shrimp feed pellet machines are built to last, using durable materials and incorporating designs that facilitate easy maintenance. This durability means less frequent breakdowns and reduced maintenance costs for feed mills. When maintenance is required, high-quality machines often feature modular designs that allow for quick part replacements, minimizing production downtime. This reliability is crucial for feed mills to maintain consistent supply to their customers and avoid the costs associated with unexpected production halts.

- Compliance with Industry Standards

As regulations in the aquaculture industry become more stringent, particularly concerning feed quality and environmental impact, high-quality shrimp feed pellet machines help feed mills stay compliant. These machines often incorporate features that ensure hygienic production, precise ingredient mixing, and minimal fines production. This compliance not only helps feed mills meet regulatory requirements but also positions them as responsible and trustworthy suppliers in the market.

- Adaptability to Technological Advancements

The aquafeed industry is constantly evolving, with new technologies emerging to improve feed quality and production efficiency. High-quality shrimp feed pellet machines are often designed with future upgrades in mind. They may feature modular components that can be updated or replaced as new technologies become available. This adaptability ensures that feed mills can stay at the forefront of technological advancements without the need for complete system overhauls.

- Enhanced Product Differentiation

For feed mills, the ability to produce high-quality, specialized shrimp feed can be a significant differentiator in a competitive market. High-quality pellet machines allow for the production of feeds with specific characteristics – such as enhanced water stability, specific sinking rates, or unique nutritional profiles. This capability enables feed mills to cater to niche markets or develop premium product lines, potentially commanding higher prices and improving profit margins.

- Improved Traceability and Quality Control

Modern, high-quality shrimp feed pellet machines often come equipped with advanced monitoring and control systems. These systems can track various production parameters in real-time, providing valuable data for quality control and traceability. For feed mills, this means enhanced ability to monitor and control the production process, ensure consistent quality, and quickly identify and address any issues that arise. This level of control and traceability is increasingly important in an industry where end-users demand transparency and consistency.

- Sustainability and Environmental Considerations

As the aquaculture industry faces increasing pressure to adopt sustainable practices, high-quality shrimp feed pellet machines can play a crucial role. These machines often offer better feed conversion efficiency, reducing waste and environmental impact. They may also be capable of processing alternative, more sustainable ingredients effectively. For feed mills, this means the ability to produce eco-friendly feed products, aligning with market trends towards sustainability and potentially opening up new market segments.

Conclusion

In conclusion, a high-quality shrimp feed pellet machine represents far more than just a piece of equipment for feed mills. It is a strategic asset that can drive efficiency, quality, innovation, and competitiveness. By investing in top-tier pellet machines, feed mills position themselves to meet the evolving demands of the shrimp farming industry, comply with regulatory requirements, and potentially lead in product innovation and sustainability.

The implications of such an investment extend beyond immediate production capabilities. They touch on aspects of brand reputation, market positioning, operational efficiency, and long-term sustainability. As the aquaculture industry continues to grow and evolve, the role of high-quality feed production equipment will only become more critical.

For feed mills looking to secure their position in this dynamic market, investing in high-quality shrimp feed pellet machines is not just an option – it’s a necessity for future success and growth.