The sawdust wood pellet mill is a professional equipment for processing biomass pellet fuel. The emergence of this wood pelletizer equipment not only processes the previously wasted precious renewable resources into biomass pellet fuel, but also effectively protects the living environment on which we live.

The pellet fuel processed by sawdust pellets has the characteristics of high density, high calorific value, sufficient fuel, low cost, convenient use, cleanliness, easy transportation and storage, etc. It can be used as gasifier, heating furnace, agricultural greenhouse, boiler and power generation. of fuel.

Some users are also worried about the economic benefits of biomass fuels in the process of investment. Now let’s introduce the economic benefits of biomass fuels processed by sawdust pellets.

In the international market, the application and research and development of sawdust wood pellet mill are much earlier. Nowadays, biomass solidified molding fuel has been commercialized in Japan, the European Union, the United States and other countries and regions. It is very popular and convenient, and can be bought in supermarkets. In my country’s market, it appears as a new product.

Let’s take wood chips and sawdust as examples to explain the significance of biomass fuel processed by sawdust pellets:

Take sawdust as an example: the calorific value is about 0.8-0.9 times that of coal, that is, 1.1 ton of sawdust briquette fuel is equivalent to 1 ton of coal. If the sawdust briquette fuel is burned in a biomass combustion boiler, its combustion efficiency is 1.3 times that of a coal-fired boiler. -1.5 times.

Therefore, the heat utilization rate of 1 ton of sawdust briquette fuel is equivalent to that of 1 ton of high-quality coal, or even higher. (Related post: wood pellet mill for sale)

The waste emissions CO2 emissions from burning sawdust pellet fuel are close to zero. NO2 emission is 14mg/m³. SO2 and soot emissions are far lower than the national standard. Therefore, the pellet fuel processed by sawdust pellets has important environmental protection significance and energy saving significance, which lays the foundation for its market application.

1. Mold of the wood pellet mill machine is blocked?

What should I do if the mold of the wood pellet mill machine is blocked?

There are two reasons for the blockage of the sawdust wood pellet mill, one is too fast and the output is too slow, and the other is that there are impurities in the raw materials, such as nails, bricks, etc. Generally, both situations will occur.

The solution is to block the die of the wood pellet maker machine. The solution is to first turn off the equipment, then open the die cover, loosen the inner die nut, and pour out the extruded raw material (if it is a brick or nail). Need to take it out. After removing, tighten the nut.

In the production process of the sawdust pellet machine, due to the improper control of raw material moisture and the excessive size of the raw material pellets, the mold of the sawdust machine will be blocked, and manual blocking is very difficult.

Larger wood chipper manufacturers will purchase special die punches. Hole equipment was blocked, but it was a headache for a new friend who just invested in the wood pellet production industry. Today I teach you a simple blocking method. (Related post: fuel pellet plant)

In the wood pellet production process, due to power failure or other reasons, the mold is blocked, especially the small hole mold is difficult to clean.

It is more common in wood pellet mill equipment to drill the material with a power drill, which wastes time and easily destroys the smoothness of the die holes. After stamping, it needs to be re-grinded for normal use, which affects work efficiency.

A more efficient way is to use oil to cook the ring mold, i.e. use an iron oil pan, put the waste oil, put the plug mold into the oil pan so that the plug hole is completely immersed in the oil and then heat the bottom of the oil pan until the material in the plug hole Make a popping sound, that is, take out the blocked mold, re-install the machine after cooling, adjust the gap between the mold rolls, and according to the operation requirements of the wood pellet mill, the material in the blocked mold can be quickly cleaned by re-driving. Drops and does not destroy the smoothness of the die hole.

2. How much is a biomass wood pellet mill?

For biomass wood pellet mill, everyone has been more concerned about these two issues. How much does a biomass wood pellet mill cost? What is the output per hour? The output and price of different models of wood pellet mills are definitely different.

For example, the power of MZLH660 is 132kw, and the output is 1.8-2.0t/h; the power of MZLH860 is 220kw, and the output is 3.0-4.0t/h; their prices are definitely different.

There are two types of biomass wood pellet mill: flat die pellet machines and ring die pellet machines. However, people who often pay attention to pellet machines should know. The difference between the flat die and the ring die is that the pelletizing method is different, and their molds are different.

General customers will directly ask “what is the output of biomass wood pellet mill? How much is a biomass pellet machine”. Taking a familiar mobile phone as an example, manufacturers produce a variety of different models or sizes to meet the needs of different users, such as 4.5 inches, 5.5 inches, 6.5 inches and so on. When you want to buy a mobile phone, there are different models or sizes for you to choose from. (Related post: biomass wood pellet plant in Indonesia )

Compared with the biomass wood pellet mill, the pellet machine will also produce equipment with different output during the production process. Such as 500 kg per hour, 1000 kg per hour, 1.5 tons per hour and so on.

Wood pellet pressing machines with different output are named with different models or sizes. When you are ready to buy, the pellet machine manufacturer only needs to recommend suitable equipment to you according to your requirements.

At present, there are many manufacturers of wood pellet mill on the market, and the prices of biomass wood pelletizer machines are also very different. But in general, the price of biomass pellet machine is inseparable from these factors, such as output, quality, after-sales and so on.

The quality and material of the electric control cabinet of the biomass wood pellet mill are also different due to the different manufacturers. Biomass pellet machines with high quality and excellent material are not cheap from any manufacturer.

Only when we focus on quality and quality can we choose cost-effective pellet machine equipment. For the same manufacturer, the biomass pellet mill machine with the same quality and higher output is more expensive. That is why when you ask “how much is a biomass wood pellet making machine”, the manufacturer will first ask you how much output you need.

Richi Machinery is an equipment manufacturer specializing in the wood pellet mills for sale, if you are interested in our wood pellet mill projects and solutions, please leave your needs and email, WhatsApp and other contact information, our sales staff will provide professional answers and corresponding product pictures, videos and quotations.

If you need to go to Richi Machinery, you can choose the biomass wood pellet mill that suits you according to your output.

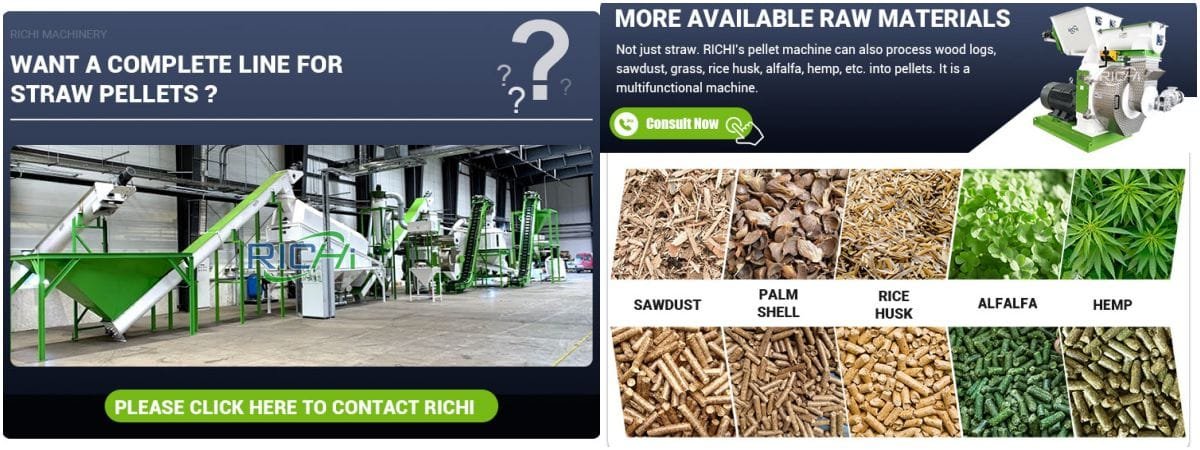

3. What are the raw materials of wood pellet mill?

I believe that everyone is no stranger to the word “sawdust wood pellet mill machine”. The so-called wood pellet mill is a mechanical device used to make wood chips into biomass fuel pellets, and the produced pellets can be used as fuel.

The raw materials of the wood pellet machine are some wastes in life and production. It successfully realizes the reuse of resources, which not only saves resources, but also protects the environment.

However, not all wastes in life and production can be regenerated into pellets. Here is an introduction to the raw materials of the wood pellet machine to help you make better use of the wood pellet mill:

(1) Crop residues: including cotton straw, wheat straw, rice straw, corn straw, corn cob and other grain straws, etc. In addition to being a raw material for energy generation, crop residues have other uses. For example, various straws such as corn straw, wheat straw and cotton straw can be processed and mixed with resin to make fiber board; these straws can also be directly returned to the field as fertilizer.

(2) Fibrous materials: The length of fibrous materials should be controlled, generally not exceeding 5mm, otherwise it is easy to cause blockage of the wood pellet mill.

(3) Sawdust sawn by band saw: Sawdust sawn with band saw can be said to be the best material for making wood pellets. It has the best particle size. The pellets made with sawdust have stable yield, smooth pellets and hardness. High, low energy consumption and other characteristics.

(4) Sand light powder in board factory and furniture factory: sand light powder has a light weight and is easy to block. When using it to make pellets, it is recommended to mix wood chips together, each accounting for about 50%, to achieve the best effect.

(5) Small shavings from furniture factories: Although shavings are also one of the raw materials of the wood pellet machine, they must be crushed before they can be used because of their large particle size and easy blockage.

(6) Leftovers of wooden boards and wood chips: Because of their large size, the leftovers of wooden boards and wood chips must be crushed before they can be used.

The use of wood pellet mill not only solves the problem of waste storage, but also produces new benefits. However, in order to use it better, the raw material requirements must be strict, otherwise it will not only fail to produce qualified pellets, but also cause damage to the wood pellet making machine.

RICHI MACHINERY focuses on wood pellet mill for sale. Also focuses on technical innovation and sustainable development all the time. It ranks as one of domestic leading manufacturers in research & development capability, manufacturing capability and product quality.

Main products include 8 categories of host products, such as silo series, hammer mill series, feed pellet mill series, wood pellet making machine series, fish feed extruder series, dryer series and cooler series, as well as accessories for pellet machinery, such as ring die, press roller,roller shell and cylinder.

If you want to know more about wood pellet machine for sale Slovakia, wood pellet mill for sale Romania, wood pellet mills for sale Austria, wood pellet mill for sale Australia, wood pellet mill for sale Indonesia, wood pellet mill for sale Malaysia, wood pellet mill for sale South Korea, wood pellet mill for sale Netherlands, please contact Richi Machinery for details.